CASE FILE ENTRY // MATERIAL FAILURE LOG

Every defect has a story.

These case studies are fictionalized representations of real-world challenges I encountered in high-precision forging environments. Under the guidance of corporate metallurgists and NDT technicians, I traced failures back to their roots—investigating metallurgical issues like voids, porosity, and inclusions, and evaluating non-destructive testing methods and process flow.

Each reconstruction reflects how I approached failure analysis from the ground up, turning anomalies into actionable insight—while protecting client confidentiality under NDA .

🧪 Metallographic Simulations — Aluminum Alloy

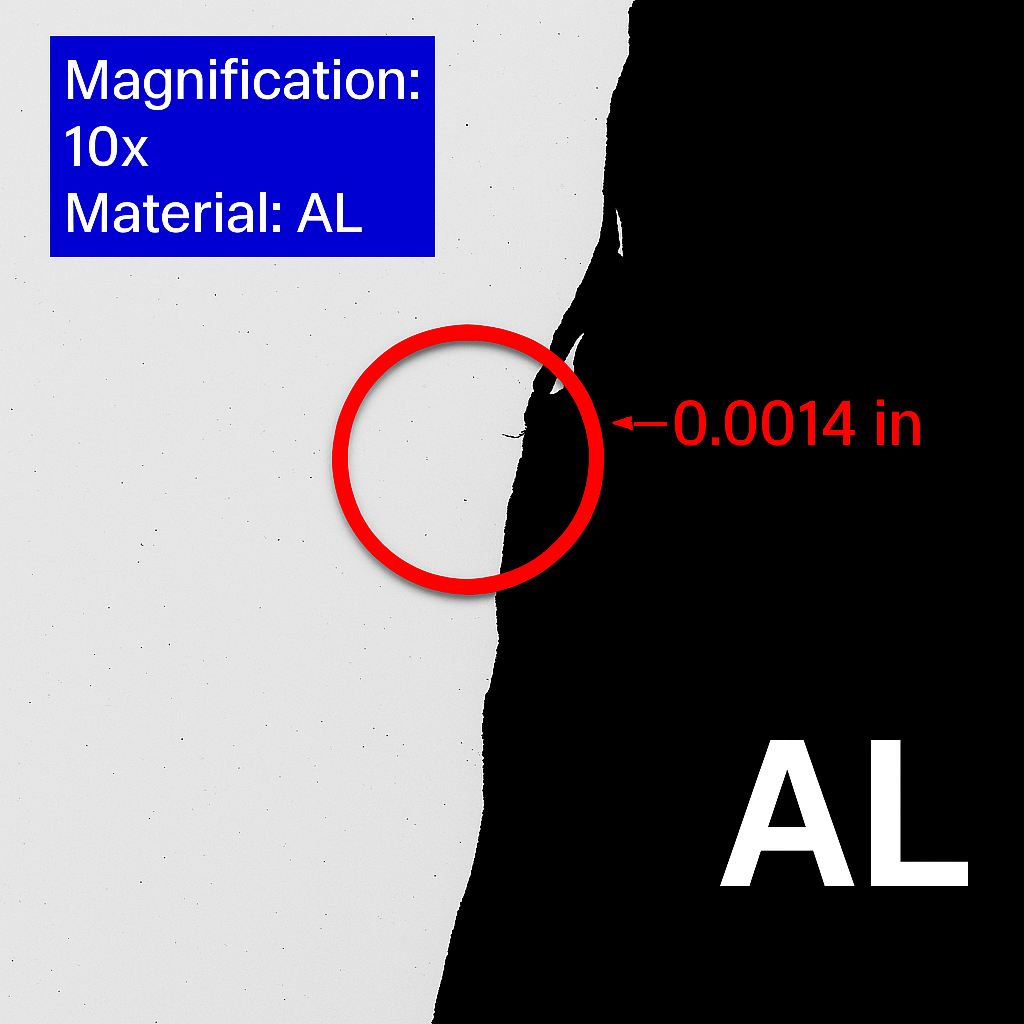

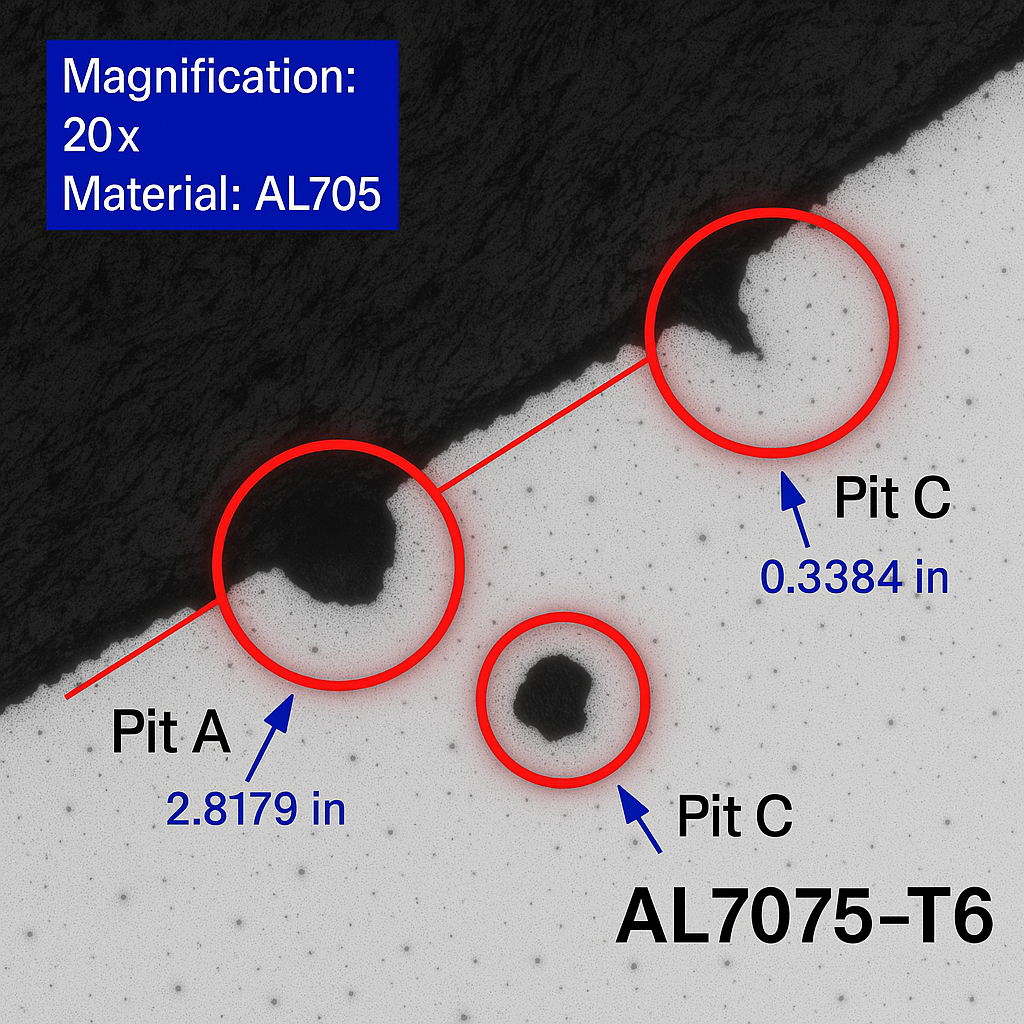

🟦 Subsurface Void Investigation — Aluminum Alloy

- Objective: Investigate machining shifts; voids found near the material boundary.

- Material: Aluminum alloy (simulated)

- Methodology: Cross-sectioned, polished, and examined under 20x lens

Findings:

- Void approx. 0.0004 in wide

- Located near outer edge — likely formed during casting or rolling

Interpretation: Subsurface voids at the billet edge may shift tooling or cause vibration during machining, compromising tolerance. Detection early in the billet lifecycle enables upstream process control.

Outcome: Helped adjust process control parameters for billet manufacturing.

⚠️ All visuals are fictionalized simulations and are NDA-safe educational content.

💻 Corrosion Comparison Dashboard

Compare common corrosion and failure types in aluminum and steel alloys. Learn visual cues, estimated depths, and forge-related causes to better diagnose material integrity issues.

⚫ Pitting Corrosion — 6261-T6 Aluminum

Localized corrosion initiating at grain boundaries or reheated zones in aluminum billets.

📝 Pit dimensions: 41.2 µm × 16.6 µm

🔍 Visual cue: Isolated elliptical void with dark rim, often adjacent to microstructural transitions.

📎 Cause: Poor passivation + chloride exposure + thermal cycling (especially in wet forge environments).

🟠 Surface Corrosion — 304 Stainless Steel

Uniform corrosion with even material loss. Passive chromium oxide layer deteriorates in high-moisture or chloride environments.

📏 Depth: ~54.9 µm

🌊 Visual cue: Smooth matte finish, etched grain texture, no isolated pits.

📎 Cause: Long-term exposure + humidity + uncoated storage — commonly observed in parts left outside prior to machining or welding.

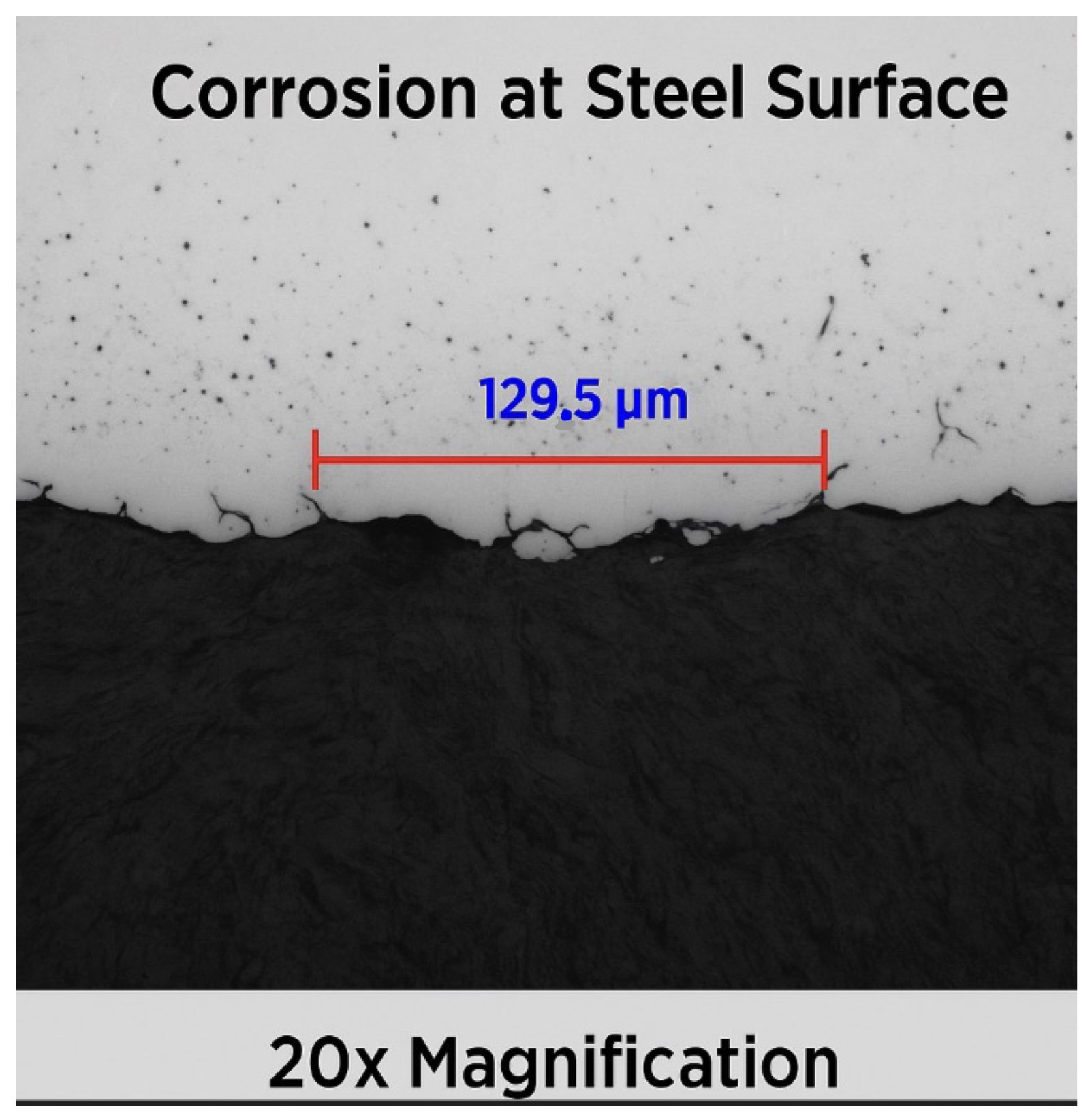

🔵 Advanced Surface Attack — Steel Alloy

Trench-like corrosion with jagged, structural loss. Accelerated by press misalignment, coating failure, and environmental contamination.

📏 Depth: ~129.5 µm

⚠️ Visual cue: Rough-edged void, often spanning multiple grains or wall surfaces.

📎 Cause: Coating breakdown + mechanical stress + electrolyte pooling during storage or forming.

🧲 Galvanic Corrosion — Bimetallic Joint

Dissimilar metals in electrical contact corrode at different rates. Common in bolted assemblies with aluminum and stainless steel.

🔩 Visual cue: Corrosion halo at fastener or joint contact.

⚡ Cause: Electrochemical potential difference + electrolyte presence.

⚪ Hydrogen Embrittlement — High-Strength Steel

Atomic hydrogen diffuses into the metal lattice, causing delayed cracking under stress. Often occurs during acid cleaning or plating of hardened components.

⚡ Visual cue: Subsurface cracks or brittle fracture in high-strength parts.

📋 Cause: Hydrogen absorption combined with tensile stress.

📊 Quick Comparison Table

| Material | Corrosion Type | Depth / Risk | Visual Cue | Cause |

|---|---|---|---|---|

| 6261-T6 Al | Pitting | 41.2 × 16.6 µm | Isolated elliptical void | Cl– ingress + thermal cycling |

| 304 S.S. | Surface Attack | ~54.9 µm | Matte grain etch | Humidity + oxide breakdown |

| Steel Alloy | Trench Corrosion | ~129.5 µm | Jagged trench void | Mechanical + coating failure |

| Al/Stl Joint | Galvanic | Variable | Halo at fastener zone | Electrochemical mismatch |

| High-Strength Steel | Embrittlement | Crack propagation | Subsurface fracture | Hydrogen + stress |

Simulated reference cases — NDA-safe visuals.

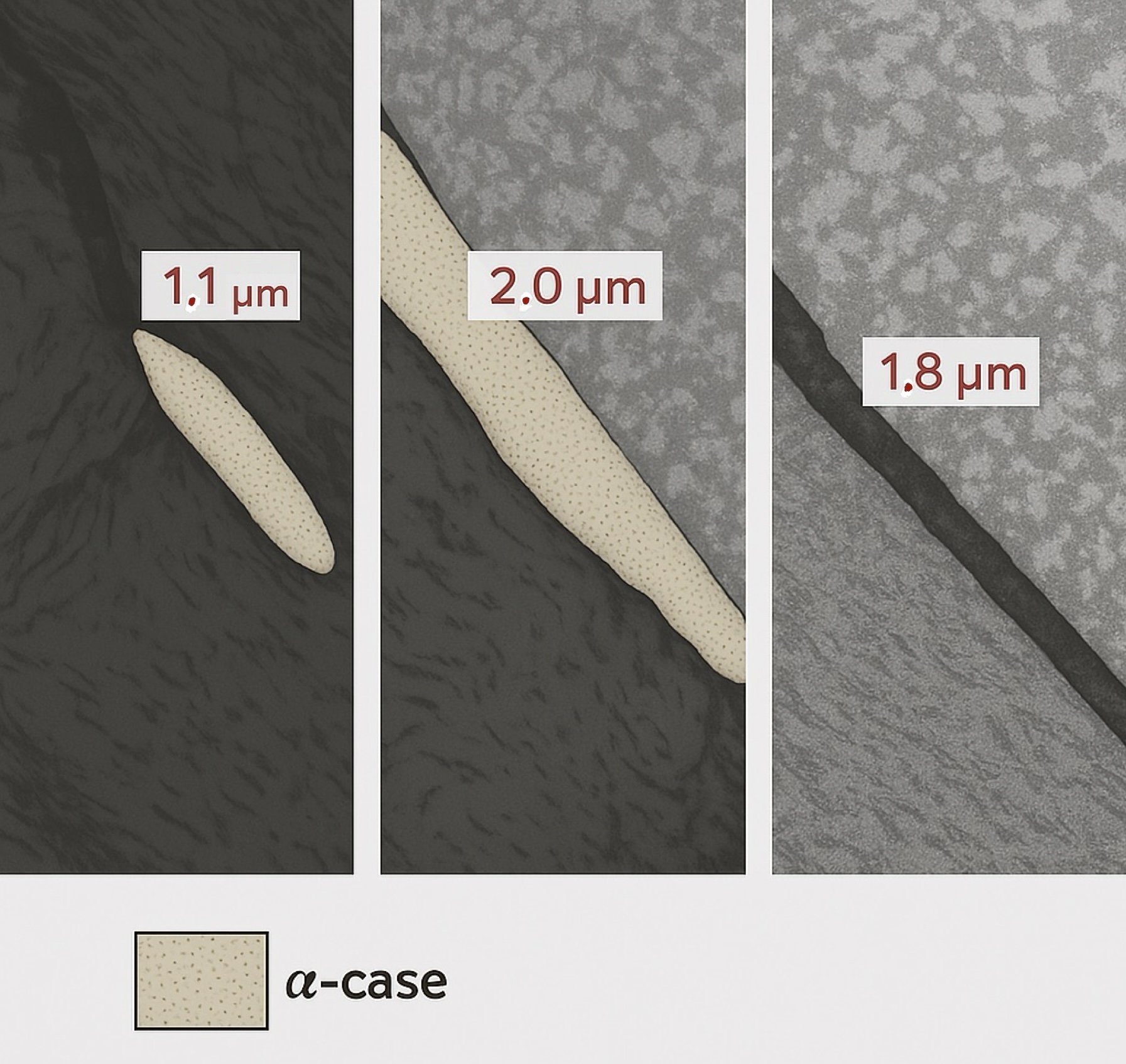

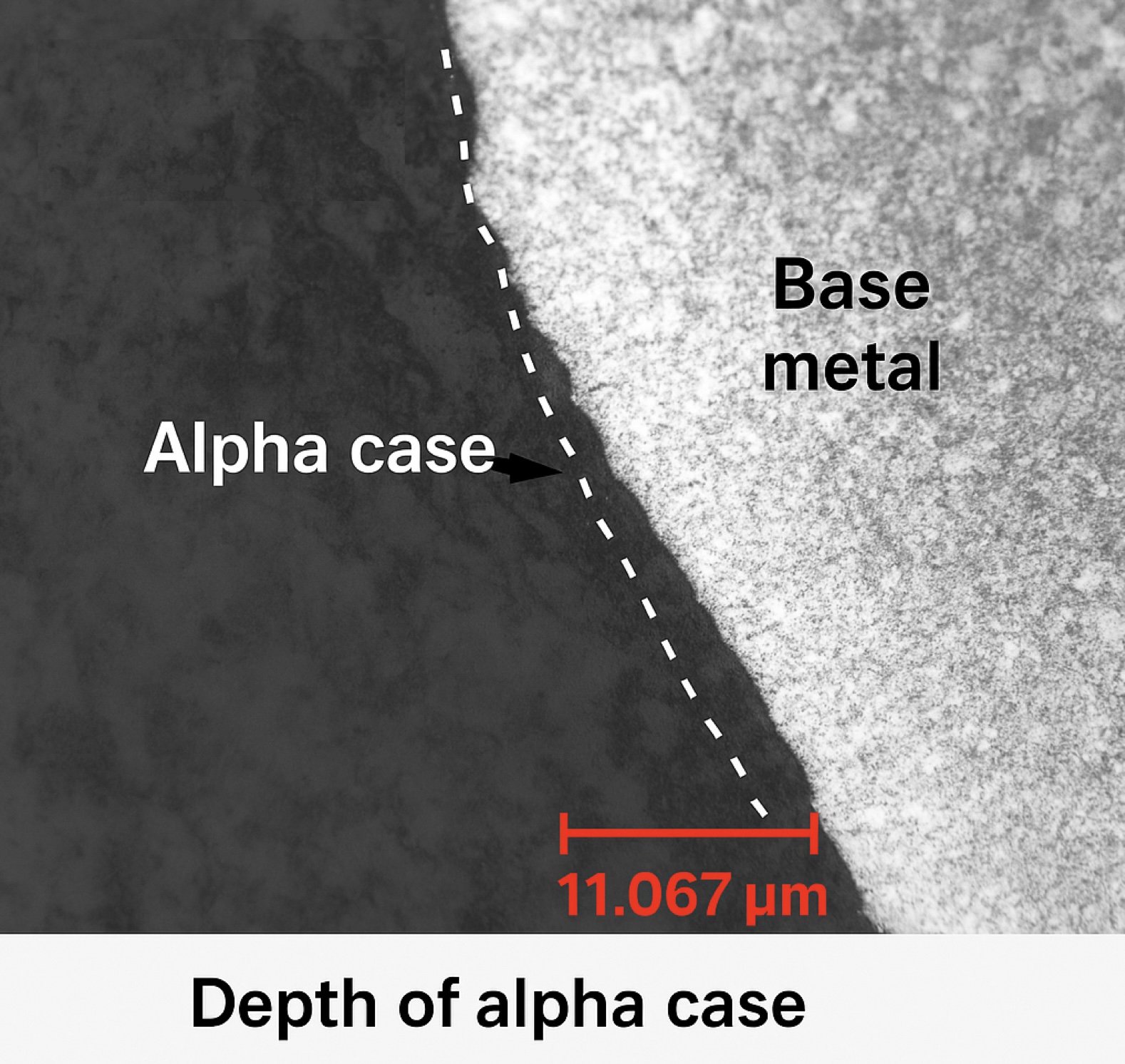

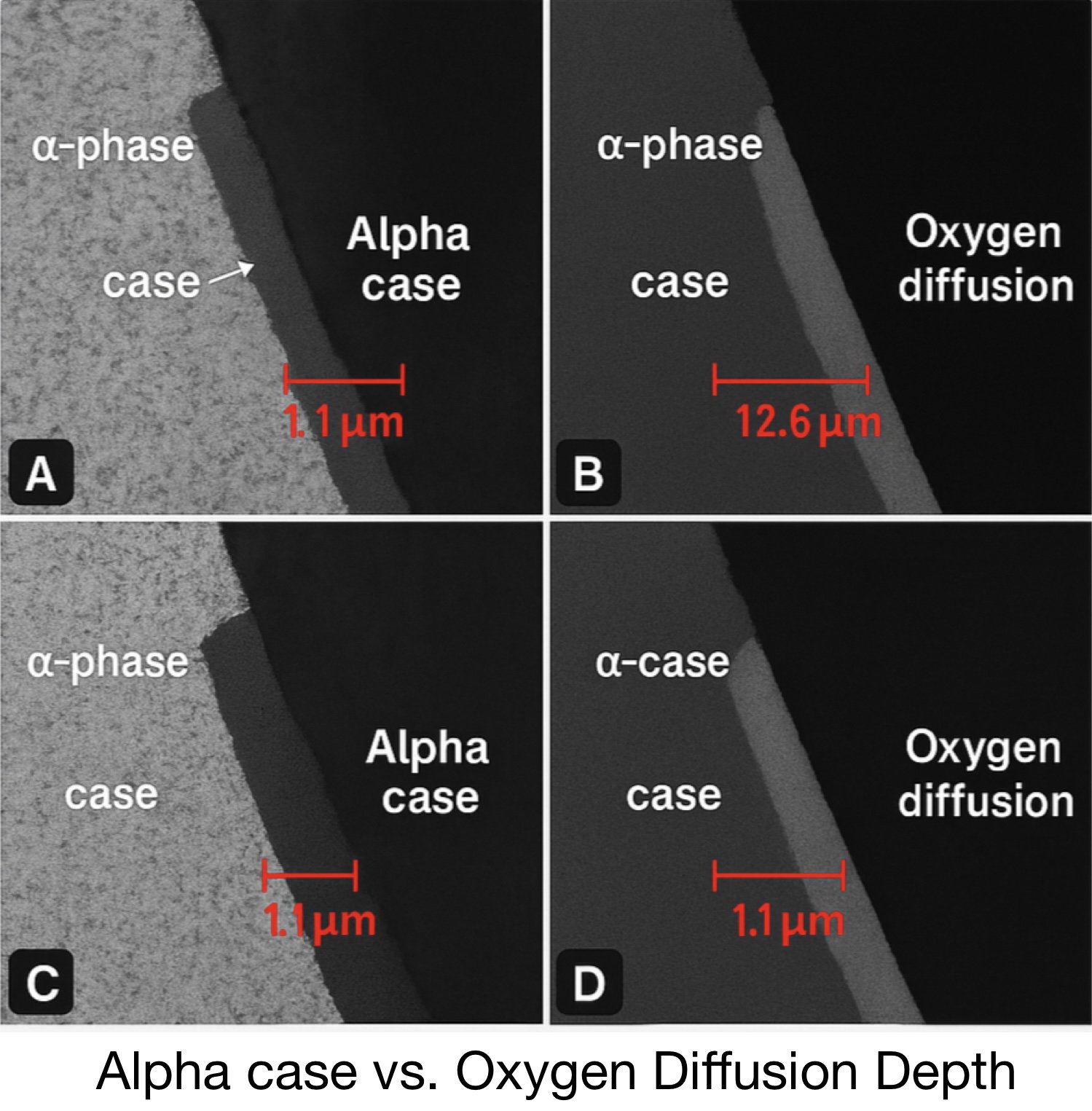

🔬 Alpha Case in Titanium — Root Cause & Visuals

Alpha case is a brittle, oxygen-enriched surface layer found in titanium alloys after high-temperature exposure. It must be minimized in aerospace and critical applications.

It forms when oxygen diffuses into titanium at forging or heat treat temperatures above 1000°F. While it can reduce ductility and fatigue life, not all alpha case is catastrophic. If within allowable limits (typically ≤0.002"), it may be tolerable or removable through surface finishing processes. Judgment depends on location, depth, and application criticality.

🧪 Simulated Microstructural Snapshots

- Material: Ti-6Al-4V alloy (forged, NDA-safe simulation)

- Prep: Polished, etched, illuminated under LED ring

- Magnification: 20x objective lens

- Focus: Identify oxidized surface depth and grain boundary patterns

Connect with Me█

LinkedIn: linkedin.com/in/audrey-enriquez-382b9b201

Email: audreyenriquez98@gmail.com

© 2025 Audrey Enriquez.

All content is shared for educational and documentation purposes only.

No proprietary or confidential information is disclosed. All rights reserved.

.png)